EPTIC TANKS / SEWAGE TREATMENT PLANTS

SOAK PITS / DRAIN FIELDS

The most common method of dealing with household waste and wastewater, in rural, unsewered areas or metros having sewage networks, is the septic system. But most people know very little about how their septic system functions.

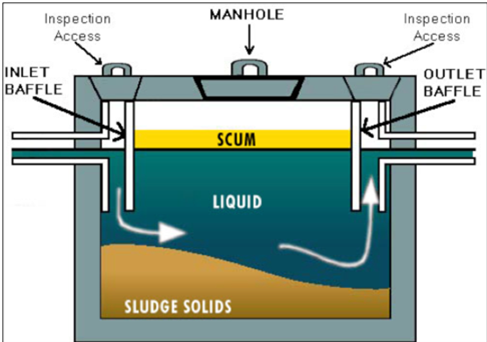

The function of the septic tank is to receive sewage and retain it for a period of time, where the following takes place:

During the retention period the floatable material undergoes microbial decomposition and forms the floating layer called “scum”.

The sewage that falls to the bottom only decomposes slightly due to the anaerobic environment and becomes a black layer called “’sludge”.

Between the scum and sludge layer is a “liquid” commonly called “clarified sewage”. It is this clarified sewage and only the clarified sewage that should trickle to the soak pits/drain fields when displaced by incoming sewage.

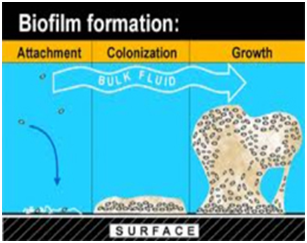

The number one reason for septic system failure is the clogging of the soak pits with solids. Scum and sludge plug the soak pits in two ways. The solids directly plug the pores or they stimulate the growth of microorganisms creating biofilms, which in turn can plug the pores and decrease filtration. Once this happens the liquid stops being absorbed effectively into the soil and begins to surface above ground.

DHARASTAN’s innovative products and technology re-engineers sewage handling to economically deliver solutions to this number one problem affecting septic tanks and sewage treatment plant’s operational efficiency while destroying the mechanism for odour production.

IN-LINE DIGESTION (ILD)

A major challenge today …. for Departments of Sanitation and Sewerage of any city (on the macro level) and various Industries viz. housing, hospitality, food, manufacturing, etc. (on the micro level) …. is the disposal of sewage economically while achieving internationally established Compliance Standards of the output (waste) water.

DHARASTAN’s unique and proprietary process of “In-line digestion (ILD)” of wastewater management involves the use of enzymes fermented in controlled fermenters from heterotrophic

Present day practices collect all the wastewater at a Central Sewage/Effluent Treatment Plant (S/ETP) in large ponds, where agitators and aerators are used to shake up and oxygenate the water, to produce aerobic bacteria in order to destroy the biological waste. These agitators and aerators regularly require maintenance while also consuming enormous amounts of energy; resulting in very high operational costs. There are some ponds in use today where no aerators are used, i.e. the pond’s process facility is based on anaerobic treatment, but, they are limited as they have a tendency to produce many foul odours.

DHARASTAN’s innovative technology re-engineers sewage handling to economically deliver numerous benefits while improving wastewater treatment efficiencies:

DHARASTAN’s unique and proprietary process of “In-line digestion (ILD)” of wastewater management involves the use of enzymes fermented in controlled fermenters from heterotrophic non-pathogenic decomposing bacteria. These enzymes are very active in degrading complex organic matter. They breakdown organic matter in such a way that only naturally occurring beneficial heterotrophic bacteria (similar to the bacteria from which the enzymes are extracted from) found in the sewage lines are able to utilize. This allows only the beneficial bacteria to grow and therefore out-compete other bacteria which can and will contribute to foul odours, corrosion of pipes and equipment and also pathogenesis.

How do we do this?

Instead of collecting the wastewater at a central treatment plant, we begin treatment of wastes upstream, at or closer to the source of the problem, i.e., treatments can begin from the individual households, societies, and also along the various junctions of the sewage network. This allows us to take full advantage of the natural retention time in the pipelines, leading to pretreatment of the wastes en-route to the treatment plant. This pretreatment process reduces the wastewater handling and maintenance requirements of the plant, thereby improving effluent treatment plant capacities.

What is the Natural Micro Flora of the sewage system?

In order to understand how the ILD (In Line Digestion) system works we will first explain the natural micro flora of the sewage system.

Domestic waste/sewage water contains lots of bacteria, being contributed largely by fecal matter, and small quantities from kitchen, laundry and bathrooms. The bacteria can be divided into 2 types:

Slime/biofilm causing sessile bacteria which contribute to the bulk of the contaminants in domestic wastewater are obtained predominately from fecal matter from our digestive tracts which also contain planktonic bacteria, but they are very few in number. Even though planktonic bacteria are outnumbered; in particular environmental circumstances, their multiplication rate is much faster than the sessile bacteria.

Sessile and planktonic bacteria both contain Aerobic, Anaerobic and Facultative Anaerobic microbes. Aerobic bacteria require oxygen for them to multiply and consume nutrients, while anaerobic bacteria cannot function in the presence of oxygen, they comprise most of the sessile bacteria. While Facultative Anaerobes function without oxygen, they can tolerate the presence of oxygen. Facultative anaerobes also have similar nutritive requirements as aerobic bacteria, thereby not contributing to contaminants in the waste water.

Sessile anaerobic bacteria, which make up the bulk of the bacteria that breed in sewerage pipelines produce various foul odors, noxious and corrosive by-products. The waste water in sewerage lines contain very little oxygen which is quickly depleted by aerobic bacteria, thus creating an anaerobic environment, thereby allowing anaerobic bacteria to quickly multiply. This condition is considered “Septic”. Even when underground piping is exposed to air, not enough oxygen is dissolved into the water to allow aerobic bacteria to thrive. Once sessile anaerobic bacteria have established themselves, oxygen cannot penetrate the slime/biofilms. In this condition, even with forced oxygenation, a septic condition will continue. These sessile bacteria harbor the notorious sulfate reducing bacteria, which is responsible for the bad smelling, corrosive hydrogen sulfide gases.

How is it done?

Utilizing waste analysis, hydrology, sewer biology transformations and plant performance analysis, a tailor made treatment process involving the continuous release of specific enzymes from specially designed sustained release packs. These enzymes target and breakdown all organic wastes found in the wastewater network like fats, oils, greases, fecal matter (carbonaceous matter), proteins, and detergents.

These packs can be introduced easily into existing septic systems and placed at strategic locations throughout the wastewater network.

DraynZyme dramatically stimulates the proliferation of useful planktonic facultative anaerobic bacteria found in small quantities in the pipelines. Once DraynZyme has been added to the system, planktonic facultative anaerobic bacteria within the system will begin to grow, reproduce and significantly become more active. These bacteria are then able to competitively consume nutrients (contaminants) from the wastewater, thereby starve the sessile anaerobic bacteria. This “competitive exclusion” is fundamental to the ILD process, where the useful bacteria will ultimately dominate the wastewater in the pipelines by out-competing the harmful bacteria for nutrients. This symbiosis vastly improves the wastewater treatment process by sharply reducing the foul odors and other corrosive gases, increasing influent biodegradability, decreasing total suspended solids (TSS). Eventually the activated biomass will remove the biofilm that prevents water from being absorbed into the surrounding soil thereby improving wastewater handling capacities.

RESULT: THE ILD PROCESS COMPLETMENTS EXISTING WASTEWATER HANDLING PROCESSES.

What are Grease Traps?

Grease traps and holding tanks are designed to capture oil and grease from the wastewater coming from a restaurant or food serving establishment.They range in sizes up to about 20 KL or more, depending on the size of the restaurant.

The Grease Trap needs to be kept with low grease deposits, to avoid clogging the sewer system and/or blocking the drain line. To keep the system in proper working conditions the drain line needs to be periodically “SNAKED” and the Grease Trap pumped out.

To avoid these frequent and costly operations (snaking and pumping out), the system must be biologically treated. DraynZyme’s FOG Buster increases the digestion of grease and the sludge, keeping the trap clean and free of odor with minimal or no pump-outs required.

Removal of Fats, Oils and Greases (FOG’s): large quantities of FOG’s get deposited into urban wastewater networks. Most FOG’s find their way into sewage networks from households, and commercial establishments such as restaurants and food processing units. FOG’s have a tendency to solidify and collect at critical points in a sewage network, creating flow problems, odors and blockages. FOG’s released untreated into the environment block water seepage into the earths’ aquifer layers. In the ILD process of waste digestion, lipolytic enzymes such as lipase and esterase are used from bacteria which are known to degrade a very broad range of fats, oils and greases. The products of the enzyme degradation, will be made available to the systems beneficial facultative anaerobic bacteria to consume.